Crystal Evaluation

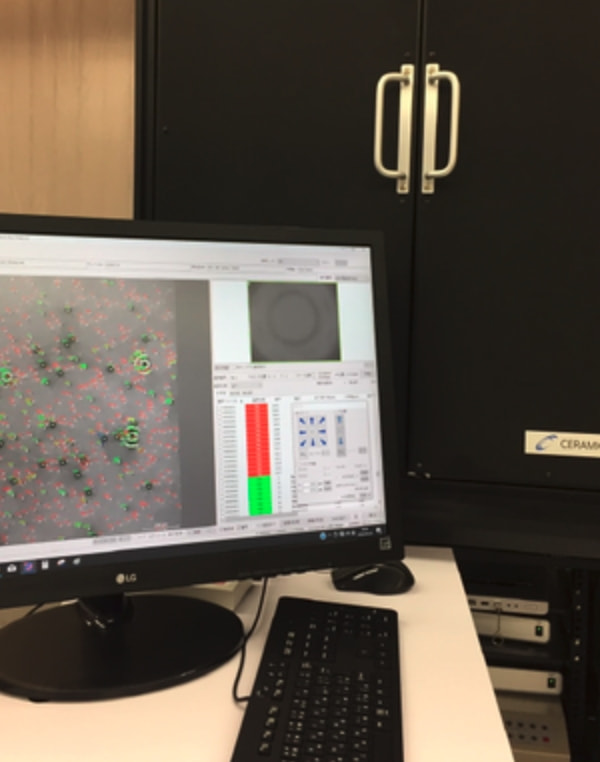

Ceramic Forum Co., Ltd. offers advanced measurement services using its proprietary 'Crystalline Tester' series (CS2 and CP1). These instruments utilize state-of-the-art technology for defect detection and crystal evaluation in semiconductor materials.

Features of Crystalline Tester CS2

-

High throughput defect detection

Equipped with automatic defect classification software for efficient inspection.

Optional automatic wafer loader/unloader enables in-line inspection in production environments.

-

High sensitivity detection of impurities and defects

Capable of inspecting in non-polarized, cross-polarized, parallel-polarized, and circular-polarized modes.

Detects even the finest defects within the crystal structure with high sensitivity.

Features of Crystalline Tester CP1

-

3D inspection using phase contrast microscopy

Non-destructive 3D mapping of internal crystal defects.

Especially effective at detecting micro-defects and fine surface distortions.

-

Automatic defect classification

Automatic defect classification software enables for efficient and accurate evaluation.

Routine inspections can be performed based on specific procedures.

Overview of Services

-

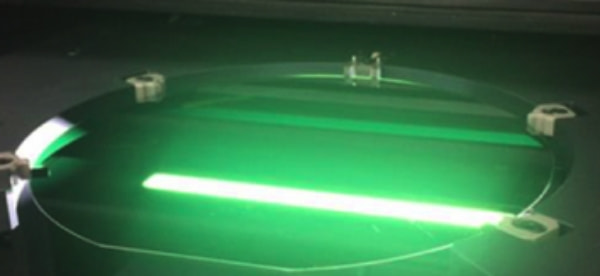

Measurement Principle

Combines transmission polarization with phase contrast microscopy for non-destructive detection of crystal defects.

-

Compatible Materials

Wide bandgap semiconductors such as SiC, GaN, and AlN.

-

Data Analysis and Reporting

Provides detailed analysis of measurement results with user-friendly reporting.