Glass

Analysis Services

Defect Analysis

We have been conducting basic research on glass melting, mainly using Czech Glass Service's bubble and rock analysis technology, dissolved gas analysis, redox measurement equipment (Rapidox), high temperature glass melting observation equipment (HTO) and high temperature glass property measurement, to clarify problems in glass melting from both theoretical and experimental perspectives.

Glass Service has over 20 years experience in glass failure measurement services and has a wide range of instruments to analyse all types of glass products. Typical examples include mass spectrometers, SEM/EDX microprobe, etc.

Physical Property Measurement

This viscosity measurement is performed over the viscosity range log(eta)[dPas] = 2 to 11.5. It is also performed using a combination of two methods to obtain the best regression equation for viscosity calculation.

For more information, click here.Manufacturing Equipment

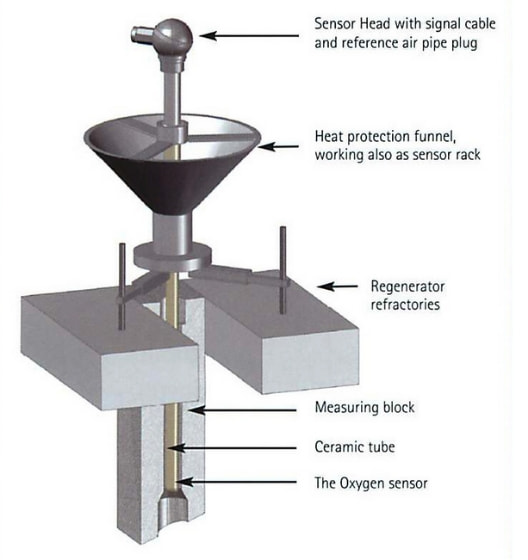

Waste gas oxygen sensor

Ceramic Forum offers an oxygen sensor manufactured by STG of Germany. When used in conjunction with STG Lamba Control, this product has the potential to reduce overall energy consumption by approximately 1.5%.

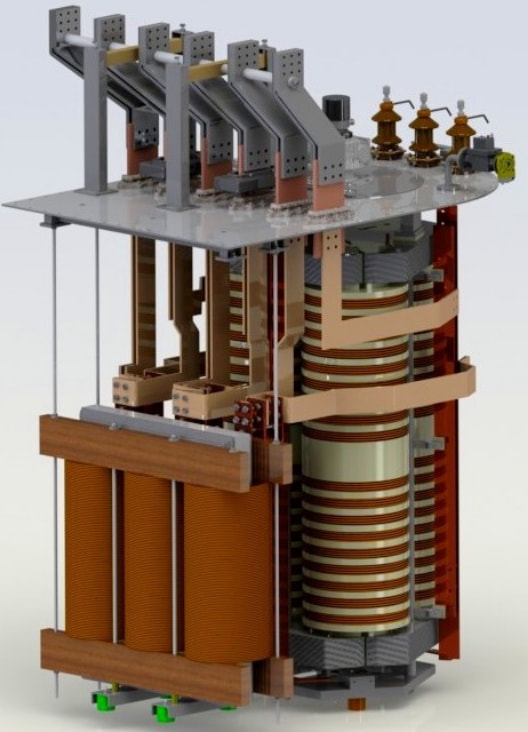

For more information, click here.Melting Furnace Transformers

Stepless control is possible with minimum and maximum voltage sensitivity.

Simple touch panel type automatic control is adopted.

No harmonics

No DC component

Efficient even at low loads

Compact design

Allowable capacity: 30 kVA to 30,000 kVA

Continuous operation for more than 10 years

Custom-made to customer specifications

For more information, click here.NIR Camera System

Overview of the in-furnace camera Unlike conventional systems where the camera is installed outside the furnace to avoid high temperatures and uses a long relay lens to capture images, a small GigE camera is integrated into the end of a 60mm diameter water-cooled pipe, allowing the camera body to be inserted directly into the furnace with the water-cooled pipe itself. This reduces the distance from the object to the sensor and provides clearer images. The original camera holder is equipped with an emergency retraction function, which automatically retracts the camera if it overheats due to a water blockage, thus preventing damage to the equipment.

For more information, click here.Glass flow sensors

The VFM system is used to measure molten glass to monitor and control the production process. When used in conjunction with an appropriately configured bushing controller, the glass flow rate can be adjusted to an accuracy of ±0.4% by weight. With proper control, the weight of the final product can be reduced by approximately 3-5%.

For more information, click here.Electrode equipment for electric melting

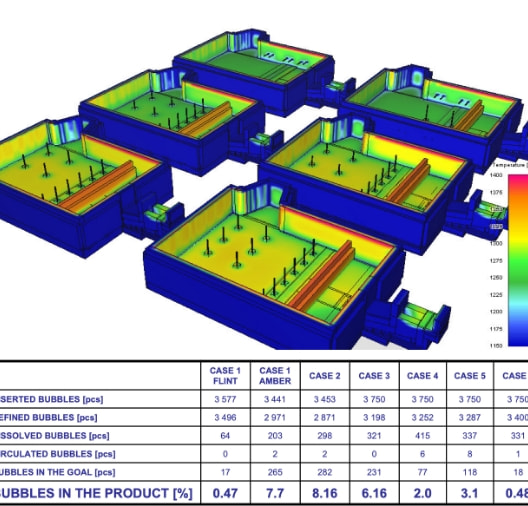

Ceramic Forum offers a commissioning service for electrode installation simulations performed by Glass Service in the Czech Republic. This simulation service has the following features.

For more information, click here.Electrode equipment for electric melting

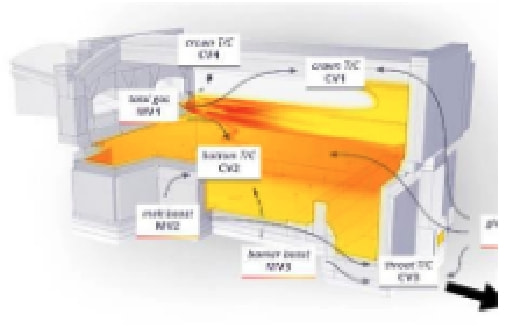

Ceramic Forum offers burners manufactured by FLAMMATEC in the Czech Republic/Germany.

This product has the following features:

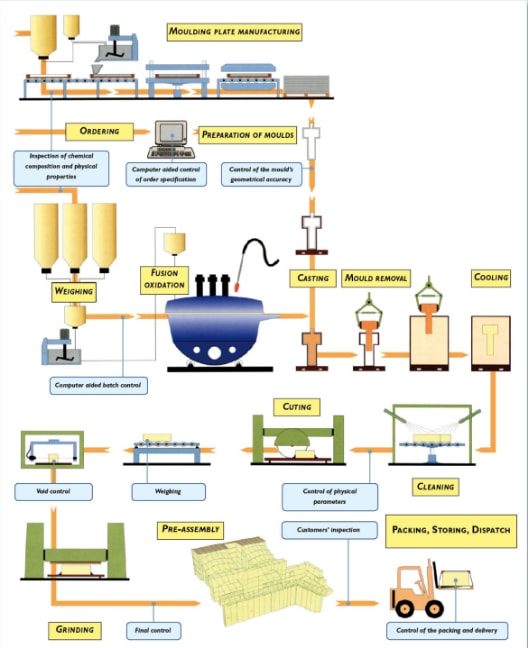

Characteristics of MOTIM electric fused refractory blocks

MOTIM refractory blocks are manufactured under strict technical control.

High purity raw materials and additives are first melted in an electric furnace. The molten material is oxidised and poured into moulds to form precise shapes. After demoulding, the blocks are placed in a controlled annealing furnace. After cleaning and polishing, each block is individually inspected and pre-assembled at the factory prior to shipment. At this stage, customer inspectors can check the assembled oven or components. Once quality is confirmed, the blocks are marked according to destination and shipping method and packed for delivery. Assembly diagrams and photographs are provided to aid correct installation.

Simulation Software

Simulation Software

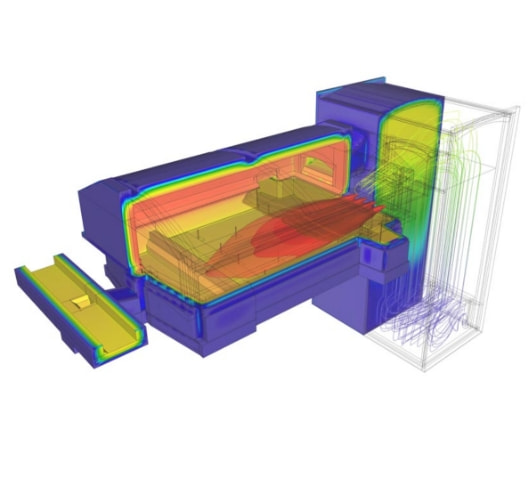

Ceramic Forum offers licenses and contract simulation services for GFM, a glass melting furnace simulation software developed by Glass Service in the Czech Republic. Customers who need simulation software for glass melting or for their own continuous quality improvement are recommended to use the GFM license. Glass Service is the world leader in modeling software dedicated to the glass industry for pre-furnace simulation. GFM was developed for glass furnace, heat exchanger, and forehearth simulation and is used by over 40 companies. During the implementation, Glass Service's expert team will train participants not only in CFD techniques, but also in the practical skills of creating glass furnace models from drawings.

For more information, please click here.Software ES.III related to automatic furnace operation

Feedback control is commonly used in glass melting furnace control, but because molten glass has low thermal conductivity and high viscosity, the input (e.g. increase in combustion gas volume) → output (increase in furnace bottom temperature) is very slow and difficult to control. ES III uses several weeks of furnace operating data from computer analysis and calculates the time function between input and output. This enables feed-forward control and stable furnace operation by predicting the effect of the input on the output. This control technology is currently being used in around 200 furnaces worldwide, contributing to significant energy savings and quality improvements.

For more information, please click here.