Glass Service Furnace Camera

Overview of the in-furnace camera

Unlike conventional systems where the camera is installed outside the furnace to avoid high temperatures and uses a long relay lens to capture images, a small GigE camera is integrated into the end of a 60mm diameter water-cooled pipe, allowing the camera body to be inserted directly into the furnace with the water-cooled pipe itself. This reduces the distance from the object to the sensor and provides clearer images. The original camera holder is equipped with an emergency retraction function, which automatically retracts the camera if it overheats due to a water blockage, thus preventing damage to the equipment.

Camera specifications

| Type | 1/2.5-inch GigE camera (power and data over a single LAN cable) |

|---|---|

| Resolution | 5MP CMOS sensor |

| Wavelength range | 0.8-1.1 µm (near infrared) |

| Field of view | 80° horizontal, 64° vertical. |

| Temperature range | 600-1600°C |

|---|---|

| Outer diameter | φ60mm |

| Total length | Customizable to any length |

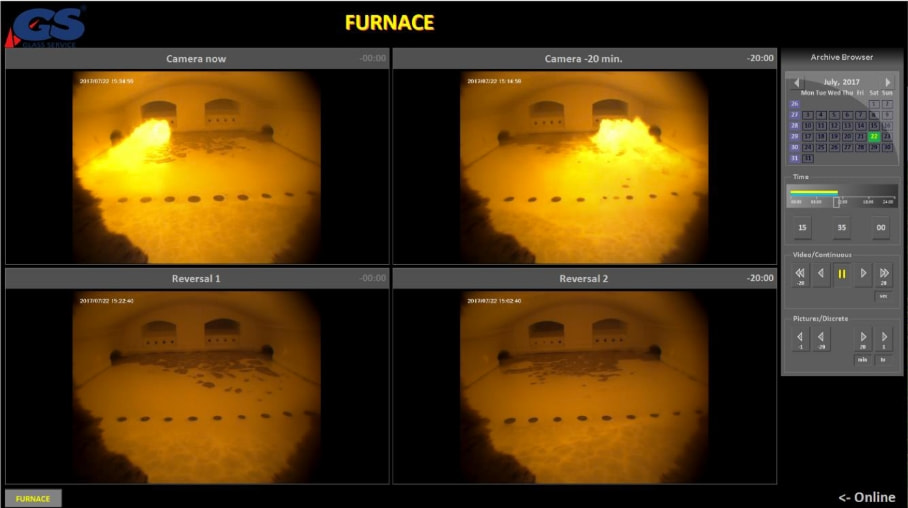

Dedicated Software

The images captured by the camera are displayed in real time on a dedicated software browser. It also has the ability to simultaneously replay past video, allowing you to monitor hourly changes in the furnace.

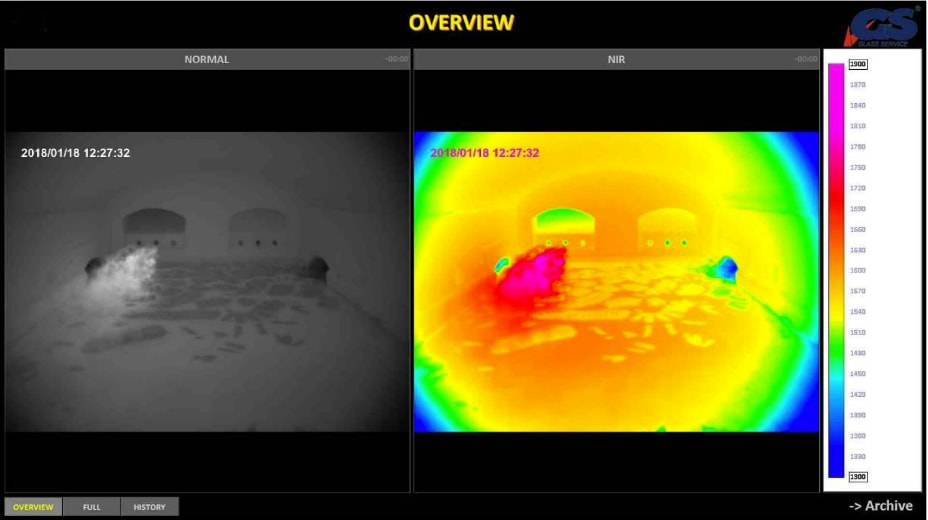

Virtual Thermocouple

The software has a real-time thermal imaging display function based on the near infrared camera images. This allows wall erosion to be monitored over time and flames not visible to the naked eye to be visualized. Clicking on a point in the thermal image displays the temperature at that location. This feature, called 'virtual thermocouple', allows users to determine temperatures in areas where physical thermocouples are not installed.

Manufacturer Introduction

Glass Service,a.s. (Czech Republic)

Glass Service is a Czech company specializing in contract glass analysis and the manufacture of various glass melting technology equipment.

They are dedicated to providing innovative products and services by combining fundamental technology with manufacturing techniques. Their flagship product, the advanced control system (ESⅢ), integrates IoT with glass production and has attracted considerable attention.