Physical Property Measurement

High Temperature Viscosity Measurement

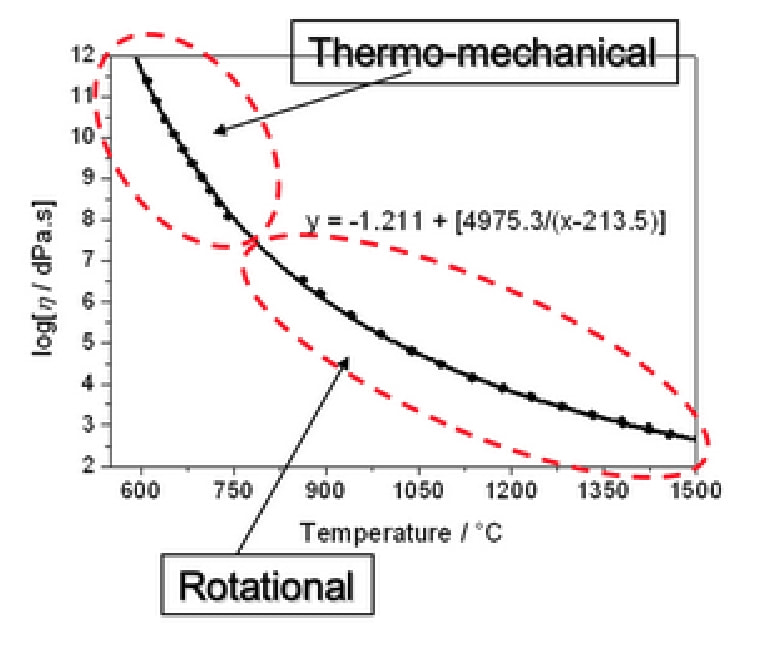

This viscosity test covers a wide range from log(η)[dPas] = 2 to 11.5.It combines two methods of measurement to derive an optimum regression equation.

| Low viscosity range (log(η) = 2-6): | |

|---|---|

| Measured with a rotational viscometer | (850-1500°C) |

| High viscosity range (log(η) = 8-11.5): | |

| Measured by thermomechanical analysis | (600-750°C) |

The combination of these allows accurate viscosity estimation over a temperature range of 600°C to 1500°C.

Values above log(η) = 13-14.5 (annealing and strain points of glass) and temperatures above 1500°C can also be estimated with high accuracy.

| Sample required | approx. 300-500g glass cullet |

|---|---|

| Delivery | Within 3 weeks of receipt of sample at Ceramicforum |

Workflow - Order to Delivery (Viscometry)

-

To request a quotation, please contact us by email or telephone. Please provide as much information as possible about the composition of your glass sample. This is necessary to check for gas formation during melting and damage to the measuring machine.

-

Please send us your sample. We will forward it to Glass Service in the Czech Republic.

On request you can also send the samples directly to Glass Service.

Note: A 400g cullet is required. For the low viscosity test a piece of glass at least 30 x 5 x 5 mm is required. If not, an additional remelting fee may apply. -

A preliminary report (PDF) will be emailed to you by Glass Services. If you have any questions about the content, please contact GS or us. We will then send you a printed copy of the technical report and an invoice by post.

| Viscosity point | Viscosity logarithm log(77/dPa.s) | Temperature [°C] |

|---|---|---|

| Viscosity point | 2 | 1455.3 |

| Fusion Gob point | 3 | 1207.9 |

| Liquidus temperature | 3.7 | 1084.8 |

| Working point | 4 | 1040.6 |

| Sink point | 4.22 | 1010.8 |

| Flow point | 5 | 919.8 |

| Softening point | 7.55 | 718.5 |

| Annealing point | 13 | 526.1 |

| Tg Transition | 13.4 | 517.1 |

| Strain point | 14.5 | 494.3 |

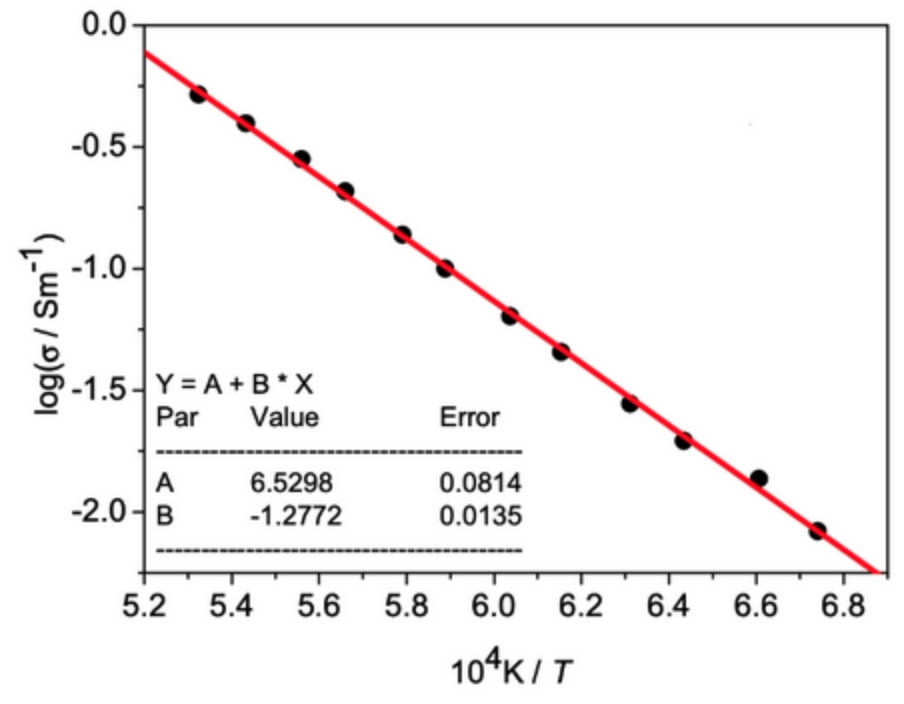

Electrical conductivity measurement

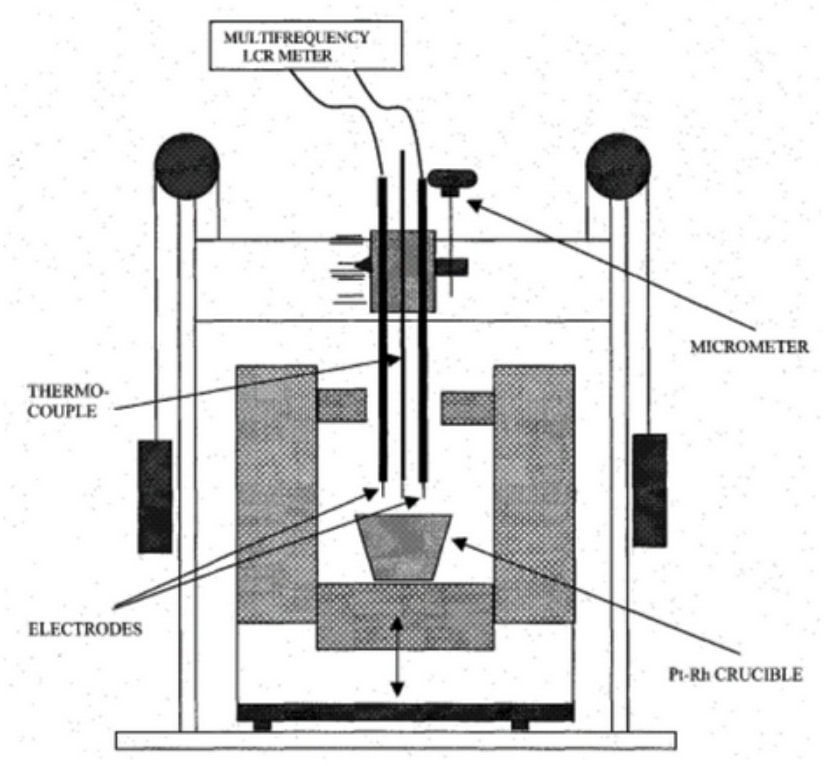

Measurements are made with an automatic RLC bridge BM595 (Tesla Brno), 20 kHz, 50 mVAC. Electrodes Pt-Rh, circular (ø5mm), distance 15mm.

Cell constants calibrated with 1 mol/dm³ KCl solution at room temperature.

Regression analysis is provided in the form of the Arrhenius equation.

| Measuring temperature range Max | 1550°C |

|---|---|

| Temperature interval every | 40-50°C |

| Sample volume max | 1550°C |

| Temperature interval approx | 200g glass cullet |

| Delivery time | Approximately 3 weeks after sample arrival at our company |

Workflow - From Order to Delivery (Conductivity)

-

If you are requesting a quotation, please provide us with composition data, including temperatures at which there is a risk of crystallization. This information is necessary to predict gas formation during melting and to ensure accuracy.

-

Please send samples to us or directly to Glass Service if required.

Approximately 200 grams of clean cullet is required. -

Glass Service will provide you with a preliminary report in PDF format. If you have any queries, please contact GS or us. A printed version and invoice will be sent to you by Ceramicforum.

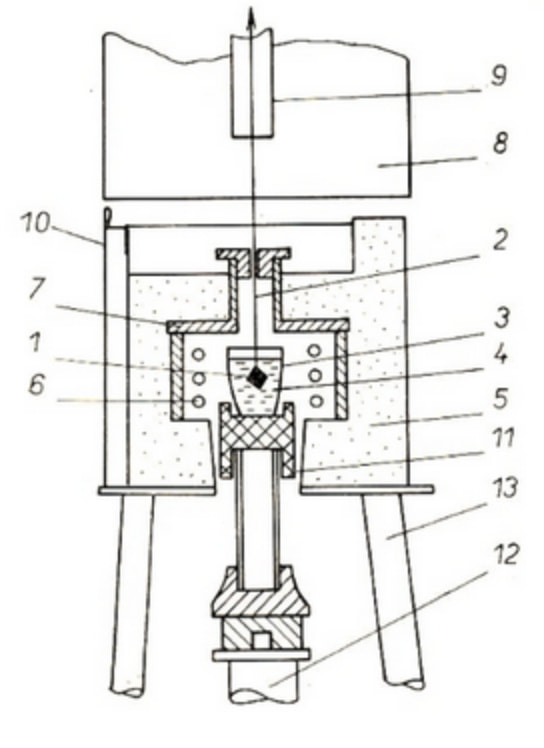

Density measurement

Based on Archimedes' principle, measured at room temperature and in the molten state using platinum apparatus.

| Temperature range | 950-1550°C |

|---|---|

| Sample | approx. 300-500g of glass cullet |

| Delivery | Within 3 weeks after sample arrival at Ceramicforum |

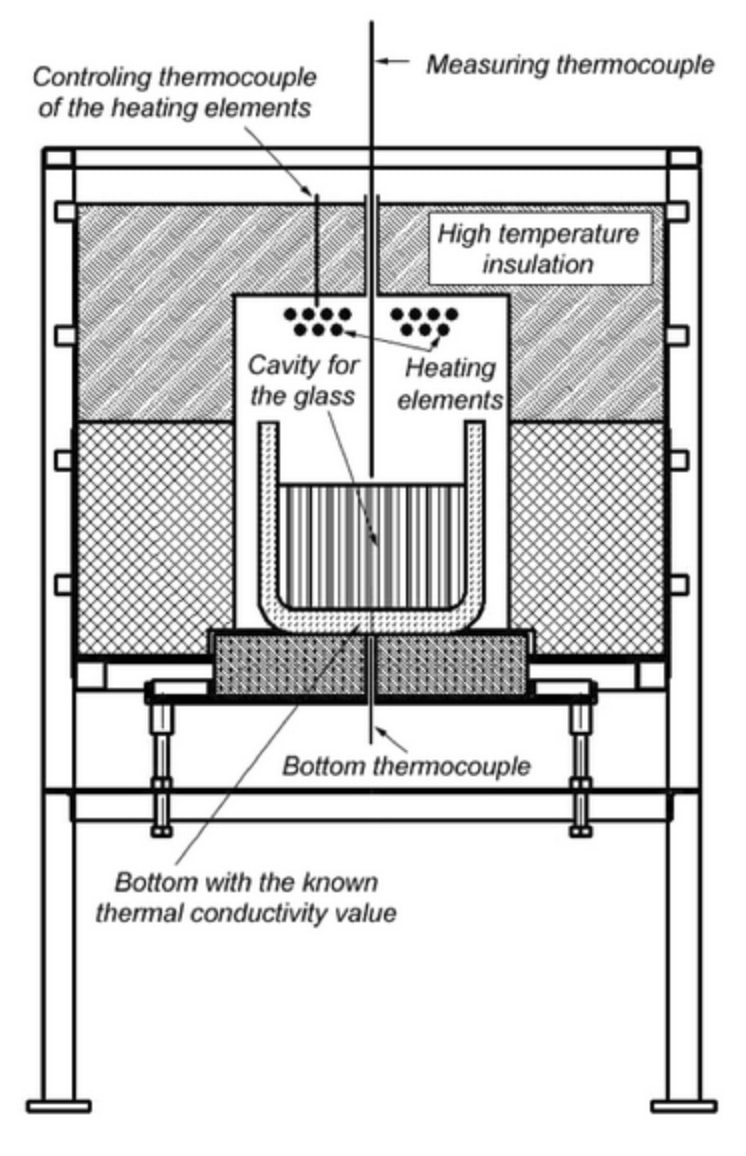

Thermal conductivity measurement

The measurement is carried out in a special furnace with the following characteristics

SiC heat source

High insulation (except base)

Base refractory of known conductivity

Vertical temperature distribution monitoring by moving thermometer

Base temperature measured externally

| Sample | approx. 50-60 kg of glass cullet |

|---|---|

| Delivery | approx. 5 weeks after sample arrival at Ceramicforum |

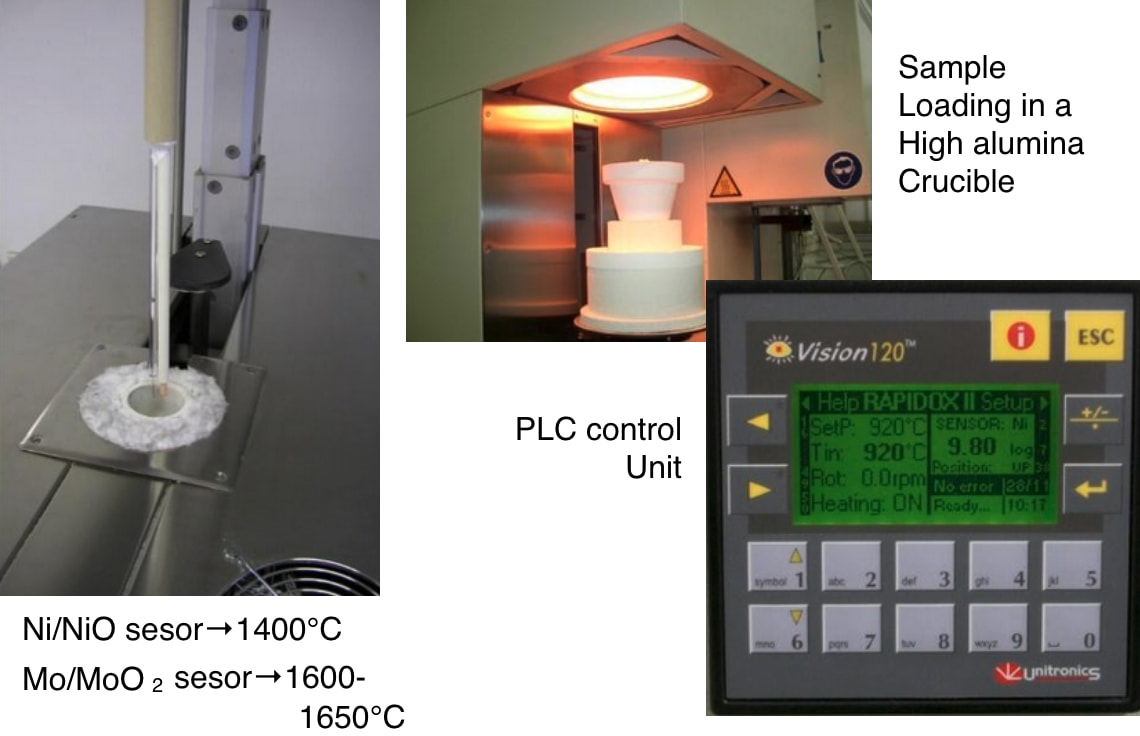

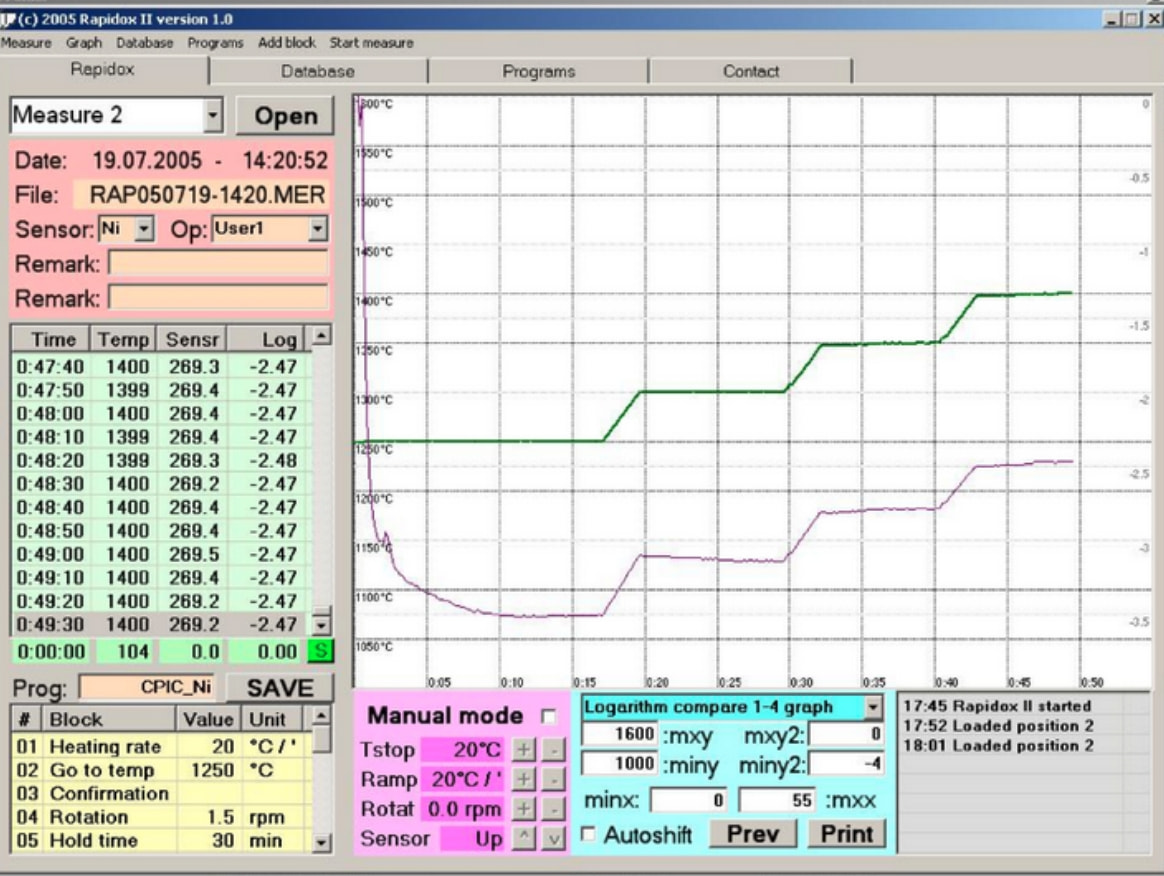

Redox measurements

Standard measurement of redox in molten glass by electrochemical methods.

- Using Glass Service's Rapidox II.

- The molten glass is rapidly heated, melted and stabilized.

A sample comparison temperature of 1300°C is used to compare several samples according to a simple temperature pattern. - Two sensors are used for repeatability.

- Redox is expressed as the logarithm of the oxygen partial pressure.The oxygen content in the melt can be converted to the mass units used in the redox calculation using the oxygen solubility data.

- Approximately 2 kg of clean glass cullet or product is required per measurement.

Workflow - Order to Delivery (Viscometry)

-

To request a quotation, please contact us by email or telephone. Please provide as much information as possible about the composition of your glass sample. This is necessary to check for gas formation during melting and damage to the measuring machine.

-

Please send us your sample. We will forward it to Glass Service in the Czech Republic.

On request you can also send the samples directly to Glass Service.

Note: A 400g cullet is required. For the low viscosity test a piece of glass at least 30 x 5 x 5 mm is required. If not, an additional remelting fee may apply. -

A preliminary report (PDF) will be emailed to you by Glass Services. If you have any questions about the content, please contact GS or us. We will then send you a printed copy of the technical report and an invoice by post.