SiC Related Products / Services

What is SiC?

SiC (Silicon Carbide) is a compound semiconductor composed of silicon (Si) and carbon (C). With a breakdown electric field strength 10 times greater and a bandgap 3 times wider than silicon, SiC surpasses the limits of conventional silicon and is highly anticipated as a next-generation material for power devices.

SiC semiconductors also have feature high electron mobility and excellent heat resistance, enabling operation in high temperature environments where conventional silicon semiconductors cannot perform. In addition, their low power loss contributes to energy efficiency.

Because of these characteristics, SiC devices are increasingly used in demanding applications such as solar and wind power systems, and railway inverters, where high voltage and high speed control in harsh environments is essential.

We offer reliable supply and strict quality assurance, supporting both R&D and mass production for advanced semiconductor manufacturers.

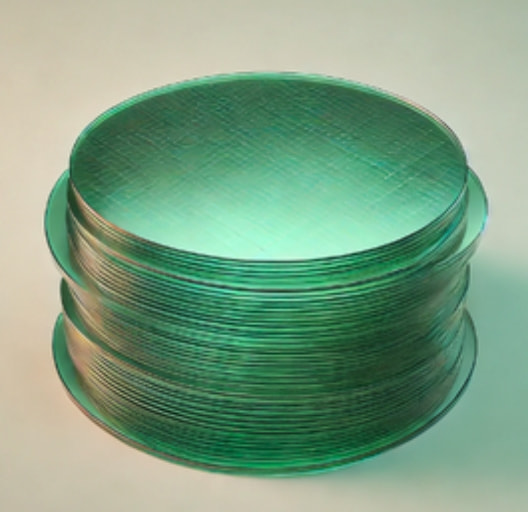

High-Quality SiC Wafers by Ceramic Forum

Ceramic Forum provides high-quality SiC wafers for next-generation power devices, sourced from trusted global manufacturers using the sublimation (PVT) method. These wafers are ideal for high-voltage and high-temperature applications.

We offer reliable supply and strict quality assurance, supporting both R&D and mass production for advanced semiconductor manufacturers.

SiC Epitaxial Deposition Services

We provide contract-based SiC epitaxial deposition services that are critical to improving device performance. Our services support a wide range of specifications including n-type, p-type and epitaxial layers for ultra-high voltage devices from 600V to over 10kV.

For more information, click here.SiC Foundry Services

We offer comprehensive foundry services for SiC devices, including:

Ion implantation service using energy filters, allowing high-precision control of the doping of epitaxial layers in SiC.

Ion implantation service for SiC, GaN, GaAs and other substrates at the high energies (~50 MeV) required for power device ion implantation.

Services tailored to each stage of SiC power device design, prototyping, evaluation, pilot mass production, and large-scale mass production.

CMP processing, regenerative polishing, wafer thinning, wire sawing, cleaning, process evaluation, etc. for various wafers.

For more information, click here.